Launching a soldering wire manufacturing venture can be both lucrative and challenging. This in-depth, SEO-optimized guide equips entrepreneurs with data-driven insights, cost breakdowns, and actionable strategies to build a successful, end-to-end soldering wire plant.

1. Raw Materials

A robust raw-material strategy underpins profitability. Below is a detailed annual breakdown at 100% capacity (30 MT):

| Material | Composition (%) | Annual Qty (kg) | Unit Cost (₹) | Annual Cost (₹) |

|---|---|---|---|---|

| Tin (imported) | 30 | 9,000 | 377 | 33,930,000 |

| Lead (domestic) | 67 | 20,100 | 40 | 8,040,000 |

| Antimony (import) | 0.5 | 150 | 280 | 42,000 |

| Rosin & Glycerin | – | Lump-sum | – | 120,000 |

| Furnace Coke | – | 4,000 | 6,000/ton | 24,000 |

| Total | – | – | – | 42,156,000 |

Procurement:

- Source tin from major importers in Singapore/China via LCL sea freight (lead time 20 days, ∼₹25/kg freight).

- Purchase domestic lead from Hindustan Lead & Zinc distributors; negotiate 30-day credit.

- Antimony from UK suppliers; air freight for just-in-time supply.

- Rosin from local chemical traders; secure bulk-discount MOUs.

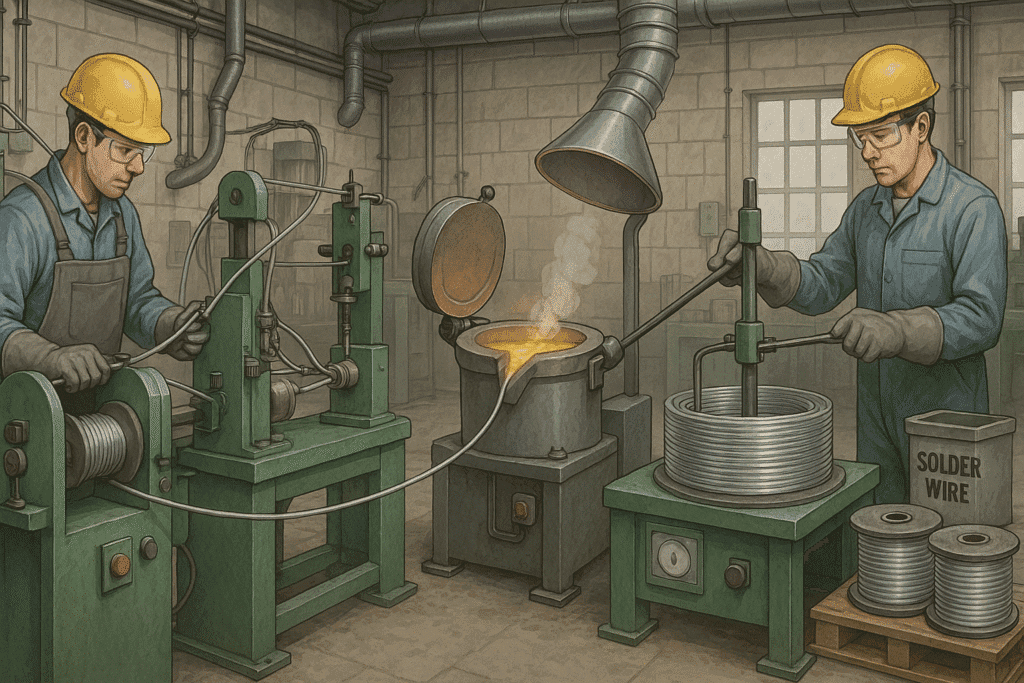

2. Machinery & Equipment

Core plant machinery for 30 MT/yr:

| Equipment | Qty | Spec | Unit Cost (₹) | Total (₹) |

|---|---|---|---|---|

| Coke-fired melting furnace (1 HP) | 2 | 500 kg melt/hr | 20,000 | 40,000 |

| Bar rolling plant (2 HP) | 2 | Rolls to Ø10 mm | 32,000 | 64,000 |

| Wire rolling machine (1 HP) | 4 | Ø1–5 mm output | 20,000 | 80,000 |

| Wire cutting machine (1 HP) | 2 | Automatic cut | 10,000 | 20,000 |

| Winding machine (1 HP) | 2 | Coil up to 100 m | 8,000 | 16,000 |

| Chemical testing bench | 1 | IS-1921/1961 | 15,000 | 15,000 |

| Weighing balances | 2 | ±0.1 g precision | 7,000 | 14,000 |

| Tools, jigs, dies | – | Set | 50,000 | 50,000 |

| Total Plant & Machinery | – | – | – | 299,000 |

Financing:

- Purchase: Bank-term loan at 11.5% p.a.

- Lease: 8–12% p.a. lease rental; 3-year payback.

- Vendor selection: Choose ISO-certified fabricators in Ahmedabad/Gurgaon.

3. Manpower Requirements

To maintain 100% capacity:

| Role | Headcount | Skills | Monthly Salary (₹) | Benefits (10%) |

|---|---|---|---|---|

| Plant Manager | 1 | Metallurgy | 45,000 | 4,500 |

| Skilled Operators | 4 | Machine ops | 18,000 each | 1,800 each |

| Unskilled Staff | 4 | Coil & packing | 12,000 each | 1,200 each |

| Accountant | 1 | Finance | 25,000 | 2,500 |

| Sales Agents | 2 | B2B sales | 20,000 each | 2,000 each |

| Total | 12 | – | 260,000 | 26,000 |

Hiring:

- Use Naukri & industry referrals for skilled roles.

- Partner with a local polytechnic for trainees.

4. Plant Setup & Infrastructure

Recommended factory: 3,000 sq ft shed.

- Land/building lease: ₹100 per sq ft/month → ₹300,000/yr.

- Civil works & utilities: ₹1,200,000 (flooring, workshops, mezzanine).

- Utilities installation:

– Electricity connection (100 kW load): ₹200,000.

– Compressed air, water treatment: ₹150,000. - Site development & fencing: ₹150,000.

- CapEx TOTAL: ~₹2,000,000.

5. Operations & Utilities

Monthly OPEX:

| Item | Load/Usage | Rate (₹) | Qty/Month | Cost (₹) |

|---|---|---|---|---|

| Electricity | 100 kW @ 8 hr | 8.50/kWh | 24,000 kWh | 204,000 |

| Furnace Coke | 0.3 t | 6,000/t | 25 t | 150,000 |

| Water | 10 KL | 25/KL | 10 | 250 |

| Maintenance (5%) | – | – | – | 15,000 |

| Consumables (flux) | – | – | – | 10,000 |

| Total/Month | – | – | – | 379,250 |

Annual OPEX: ₹4,551,000.

6. Logistics & Transportation

Inbound Materials:

- Sea freight (LCL) for tin: ₹25/kg + customs duty 2.5%.

- Road transport for lead: ₹5,000/trip, 15 days lead.

Outbound Goods: - Distribution via third-party logistics: ₹8/kg.

- Warehousing: ₹5/sq ft/month for 100 sq ft coil storage.

7. Financial Analysis

Cost per kg:

- Total annual cost (CapEx amortization ₹600,000 + OPEX ₹4,551,000 + raw ₹42,156,000 + salaries ₹3,432,000) → ₹50,739,000.

- Cost/kg at 30,000 kg → ₹1,691.

Selling Price:

- Bulk (≥500 kg): ₹2,200/kg → Margin ~30%.

- Single units: ₹2,500/kg.

| Metric | Value |

|---|---|

| Break-even volume | 12,000 kg (40%) |

| Payback Period | 3.5 years |

| ROI (5-year NPV @12%) | 28% |

8. Regulatory & Incentives

- GST: 18%.

- Uttarakhand incentives:

– Capital subsidy: 30% of plant cost up to ₹10 M.

– Power rebate: 25% for 5 years.

– Stamp duty exemption on site lease.

This comprehensive guide delivers the ultimate blueprint for establishing a profitable soldering wire manufacturing plant—spanning raw materials, machinery, finances, and government incentives to fast-track success.

Frequently Asked Questions (FAQ) – Soldering Wire Manufacturing Business

General Business Questions

Q1: What is the minimum investment required to start a soldering wire manufacturing business?

A: The total initial investment ranges from ₹14.3-50 lakh, depending on production capacity. For a 30 MT annual capacity unit, you need approximately ₹14.3 lakh, including ₹1.78 lakh for machinery, ₹10.54 lakh for working capital, and ₹1.43 lakh for own contribution.scribd+2

Q2: How long does it take to break even in this business?

A: With proper planning and execution, the business can break even within 3-4 months at 29% capacity utilization. The payback period for the initial investment is approximately 3-5 years.projectreportbank+2

Q3: What is the profit margin in soldering wire manufacturing?

A: The business offers attractive profit margins of 27-30%. With selling prices of ₹2,200-2,500 per kg and production costs around ₹1,691 per kg, the gross profit margin is substantial. projectreportbank

Technical & Production Questions

Q4: What are the main raw materials required and their composition?

A: The primary raw materials include:

- Tin (30%): ₹377/kg – imported quality

- Lead (67%): ₹40/kg – domestic supply

- Antimony (0.5%): ₹280/kg – imported

- Rosin & Glycerin for flux core

- Furnace coke for melting operationskviconline

Q5: What machinery is essential for soldering wire production?

A: Key equipment includes:

- Coke-fired melting furnace (1-2 HP)

- Bar rolling plants (2 HP)

- Wire rolling machines (1 HP)

- Wire cutting machines

- Winding machines for coiling

- Chemical testing equipment

- Weighing balanceskviconline

Q6: What is the production capacity and utilization pattern?

A: A standard unit produces 30 MT annually at 100% capacity. The utilization pattern typically starts at 60% in Year 1, increases to 70% in Year 2, and reaches 100% by Year 5. kviconline

Market & Sales Questions

Q7: Who are the main customers for soldering wire?

A: Primary customers include:

- Electronics manufacturers

- Electrical equipment companies

- Automotive industry

- Telecommunications sector

- Repair and maintenance services

- Hardware retailers and distributors scribd+1

Q8: What is the market demand outlook?

A: The market shows strong growth potential with 7% annual growth rate. Domestic demand is substantial and growing, with excellent export opportunities, particularly to Middle East countries.scribd+1

Q9: What are the different grades of soldering wire that can be manufactured?

A: Various compositions can be produced based on tin-lead ratios:

- Grade A: 60% Tin, 40% Lead (premium quality)

- Grade B: 50% Tin, 50% Lead

- Grade C: 40% Tin, 60% Lead

- Lower grades with higher lead content for cost-sensitive applications kviconline

Regulatory & Compliance Questions

Q10: What licenses and permits are required?

A: Essential requirements include:

- Business registration and GST registration

- MSME registration for government benefits

- Pollution Control Board clearance

- Factory license

- BIS certification for IS-1921/1961 standards

- Trade license from local authorities, India +1

Q11: What are the quality standards to follow?

A: Soldering wire must comply with IS-1921/1961 (Indian Standard) specifications. Quality control involves chemical testing for composition, diameter consistency, and flux core integrity.eiriindia+1

Q12: Are there any environmental concerns?

A: Yes, the process involves some pollution concerns. You need State Pollution Control Board clearance, proper ventilation systems, exhaust fans, and adequate shed height for fume removal. kviconline

Financial & Investment Questions

Q13: What government incentives are available?

A: Multiple benefits available:

- MSME subsidies and capital assistance

- State-specific incentives (e.g., Uttarakhand offers a 30% capital subsidy)

- Power rebates and stamp duty exemptions

- Tax incentives for new manufacturing units project report bank

Q14: What are the financing options?

A: Various funding sources include:

- Bank term loans at 11.5% interest

- Working capital finance

- MSME loan schemes

- Government subsidy programs

- Private investors and venture capital project report bank

Q15: What are the monthly operational expenses?

A: Key monthly costs include:

- Raw materials: ₹33-55 lakhs (varies with production)

- Electricity: ₹2.04 lakhs

- Labor wages: ₹2.86 lakhs

- Maintenance and consumables: ₹25,000

- Administrative expenses: ₹30,000kviconline

Location & Setup Questions

Q16: What is the ideal location for setting up the plant?

A: Strategic factors include:

- Proximity to electronics manufacturing hubs

- Good transportation connectivity

- Reliable power and water supply

- Access to skilled labor

- Industrial zone benefits

- Raw material supplier proximity project report bank

Q17: What is the recommended plant size and layout?

A: A 3,000 sq ft facility is recommended for 30 MT annual capacity, including production area, raw material storage, finished goods storage, quality testing lab, and administrative offices. kviconline

Operational Questions

Q18: What skilled manpower is required?

A: Essential team includes:

- Plant Manager (metallurgy background)

- 4 skilled machine operators

- 4 unskilled workers for handling/packing

- 1 accountant

- 2 sales agents

Total: 12 employeeskviconline

Q19: How long is the project implementation period?

A: Complete project implementation takes 6-9 months, including site selection, machinery procurement, installation, trial production, and commercial launch.kviconline

Q20: What are the critical success factors?

A: Key factors include:

- Maintaining consistent quality standards

- Competitive pricing strategy

- Strong distribution network

- Effective raw material procurement

- Skilled workforce management

- Continuous process improvement project report bank

- https://www.scribd.com/document/712426781/Solder-Wire-Making-Plant

- https://projectreportbank.com/soldering-wire-manufacturing-project-report/

- https://www.kviconline.gov.in/pmegp/pmegpweb/docs/commonprojectprofile/solderingwire.pdf

- https://www.eiriindia.org/project-report-handbook-soldering-wire-with-formulation-technology-2253

- https://www.mapsofindia.com/my-india/education/chapter-9-small-business-questions-and-answers-ncert-solutions-for-class-11-business-studies

- https://corpbiz.io/learning/50-small-scale-manufacturing-business-ideas-in-2024-2025/

- https://www.eiriindia.org/project-report-handbook-solder-wires-with-formulation-technology-4599

- https://testbook.com/question-answer/example-of-small-scale-industries–60bdd49c8e54838fbf083afd

- https://www.reddit.com/r/IndiaBusiness/comments/1hzgotr/need_guidance_for_starting_an_electrical_shop/

- https://prostech.vn/solder-wire-definition-selection-guide/