Starting a socks manufacturing unit presents a lucrative opportunity with the global socks market valued at USD 54.30 billion in 2025 and growing at 7.19% CAGR through 2034. In India, the market is expanding at 9% CAGR, reaching INR 126.84 billion by 2034. With a modest investment of ₹9.21 lakhs, entrepreneurs can achieve 50% capacity utilization, generating ₹15.84 lakh annual sales and ₹1.06 lakh net profit in the first year.

1. Socks Manufacturing Unit – Market Overview & Growth Prospects

The global socks market is experiencing remarkable expansion, with projections showing growth from USD 50.84 billion in 2024 to USD 100.22 billion by 2034. This represents a compound annual growth rate of 7.19%, driven by increasing consumer demand for functional, fashionable, and sustainable sock options.

Regional Market Dynamics

| Region | 2024 Market Size | Growth Rate | Key Drivers |

|---|---|---|---|

| Global | USD 50.84B | 7.19% CAGR | Fashion trends, athleisure boom |

| Europe | USD 16.27B | 7.19% CAGR | Sustainability focus, fashion culture |

| Asia-Pacific | Fastest Growth | 7%+ CAGR | Rising disposable income, urbanization |

| India | INR 95B (approx) | 9% CAGR | Growing middle class, textile hub |

India’s Competitive Advantage: As the world’s 2nd largest textile manufacturer and 6th largest exporter, India is positioned to capitalize on this growth with its established textile infrastructure and skilled workforce.

2. Raw Materials: Specifications & Cost Analysis

Primary Raw Materials

| Material | Quantity (per kg) | Cost per kg (₹) | Annual Requirement | Annual Cost (₹ lakhs) |

|---|---|---|---|---|

| Polypropylene | 60% | 85 | 1,728 kg | 1.47 |

| Blended Yarn | 30% | 220 | 864 kg | 1.90 |

| Cotton Fiber | 10% | 180 | 288 kg | 0.52 |

| Total Raw Materials | – | 140 avg | 2,880 kg | 3.89 |

Procurement Strategy

- Primary Suppliers: Source polypropylene from Reliance Industries, IOCL petrochemicals

- Yarn Suppliers: Local textile mills in Tamil Nadu, Gujarat, Punjab

- Cotton Sources: Direct procurement from cotton-producing states (Gujarat, Maharashtra)

- Credit Terms: Negotiate 30-45 day payment cycles with established suppliers

- Quality Standards: Ensure compliance with IS 15064 for textile fibers

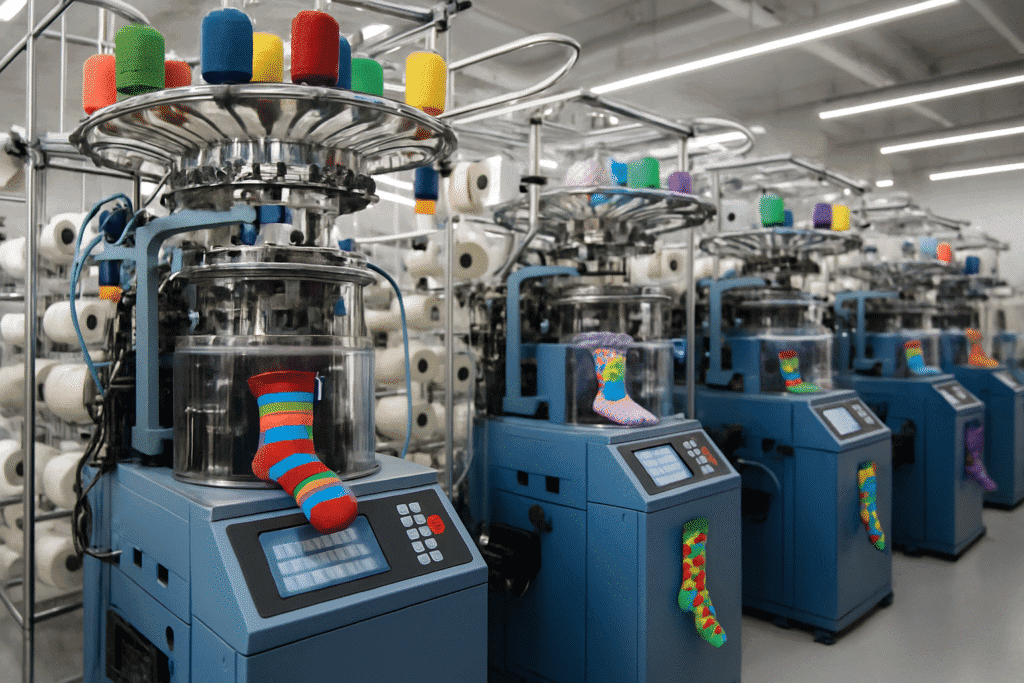

3. Machinery & Equipment Investment

Core Production Equipment

| Equipment | Specifications | Quantity | Cost (₹) |

|---|---|---|---|

| Sock Knitting Machine | 48 pairs/hour capacity | 1 | 650,000 |

| Polyester Blender | Material mixing unit | 1 | Included |

| LYCRA Yarn Processor | Elasticity enhancement | 1 | Included |

| Finishing Equipment | Cutting, packaging | 1 | Included |

| Total Machinery | – | – | 650,000 |

| GST @ 18% | – | – | 117,000 |

| Total Investment | – | – | 767,000 |

Socks Manufacturing Unit – Technical Specifications

- Production Capacity: 48 pairs/hour, 384 pairs/day, 115,200 pairs/year

- Power Requirement: 5 KW connection, 15 KWH daily consumption

- Automation Level: Semi-automatic with manual finishing

- Supplier: S L Machinery, Mundka, Delhi

4. Manpower Requirements & Structure

Workforce Composition

| Role | Skill Level | Count | Monthly Salary (₹) | Annual Cost (₹ lakh) |

|---|---|---|---|---|

| Machine Operator | Skilled | 1 | 15,000 | 1.80 |

| Production Helper | Unskilled | 1 | 12,000 | 1.44 |

| Total Direct Labor | – | 2 | 27,000 | 3.24 |

Additional Staffing (Optional)

- Quality Controller: ₹18,000/month

- Supervisor: ₹20,000/month

- Packing Assistant: ₹10,000/month

Total Employment Generation: 2-5 persons depending on capacity utilization

5. Socks Manufacturing Unit Plant Setup & Infrastructure

Space Requirements

- Land Area: 1,200 sq ft industrial space

- Layout: Production area (60%), raw material storage (20%), finished goods (15%), office (5%)

- Rent: ₹24,000/month (₹2.88 lakh annually)

- Location: Industrial estates in Uttarakhand (Haridwar, Rudrapur, Pantnagar)

Infrastructure Setup

- Civil Work: Minimal modifications required

- Electrical: 5 KW connection, backup generator optional

- Ventilation: Natural and mechanical ventilation systems

- Safety: Fire extinguishers, first aid equipment

6. Operations & Utilities

Monthly Operational Costs

| Cost Component | Monthly Amount (₹) | Annual Amount (₹ lakh) |

|---|---|---|

| Electricity (2,400 units @ ₹7) | 16,800 | 2.02 |

| Raw Materials (50% capacity) | 16,833 | 2.02 |

| Labor Wages | 27,000 | 3.24 |

| Rent | 24,000 | 2.88 |

| Maintenance & Repairs | 6,833 | 0.82 |

| Total Monthly OPEX | 91,466 | 10.98 |

Production Process

- Material Preparation: Blend polypropylene with yarn and cotton

- Machine Setup: Load raw materials into knitting machine

- Knitting Process: Automated sock formation at 48 pairs/hour

- Finishing: Cutting, shaping, quality inspection

- Packaging: Pairing, labeling, boxing for distribution

7. Financial Analysis & Projections

Investment Structure

| Component | Amount (₹ lakhs) | Own Contribution (10%) | Bank Finance (90%) |

|---|---|---|---|

| Plant & Machinery | 6.49 | 0.65 | 5.84 |

| Furniture & Fixtures | 0.50 | 0.05 | 0.45 |

| Working Capital | 2.22 | 0.22 | 2.00 |

| Total Project Cost | 9.21 | 0.92 | 8.29 |

Revenue & Profitability Projections

| Year | Capacity | Production (Pairs) | Sales (₹ lakhs) | Net Profit (₹ lakhs) | ROI (%) |

|---|---|---|---|---|---|

| 1 | 50% | 57,600 | 15.84 | 1.06 | 11.5% |

| 2 | 55% | 63,360 | 19.49 | 1.87 | 20.3% |

| 3 | 60% | 69,120 | 21.96 | 2.71 | 29.4% |

| 4 | 65% | 74,880 | 24.55 | 3.97 | 43.1% |

| 5 | 70% | 80,640 | 27.25 | 4.33 | 47.0% |

Key Financial Metrics

- Break-even: 38% capacity utilization

- Payback Period: 5 years

- DSCR: 2.89 (excellent debt servicing capability)

8. Regulatory Framework & Licensing

Required Licenses

- GST Registration: Mandatory for business operations

- MSME Udyog Aadhaar: For government incentives and benefits

- Factory License: From state labor department

- Pollution Control Board: Environmental clearance

- Fire Department NOC: Safety compliance

- Trademark Registration: Brand protection

Uttarakhand State Incentives

- Capital Subsidy: Up to 25% on fixed capital investment

- Interest Subsidy: 5% on term loans for 7 years

- Power Tariff Rebate: 50% discount for first 5 years

- Stamp Duty Exemption: On land purchase/lease agreements

- VAT/CST Exemption: Available for textile units

9. Market Strategy & Distribution

Product Pricing

- Wholesale Price: ₹28-30 per pair

- Retail Price: ₹35-45 per pair

- Bulk Orders: ₹25-27 per pair (500+ pairs)

- Premium Segment: ₹50-75 per pair (branded/designer)

Distribution Channels

- Direct Sales: Local retailers, textile shops

- B2B Sales: Garment manufacturers, institutions

- Online Platforms: Amazon, Flipkart, own e-commerce

- Export Opportunities: Southeast Asia, Middle East markets

Market Penetration Strategy

- Focus on casual socks segment (54% market share)

- Develop sustainable product lines using organic cotton

- Target athletic socks segment (fastest growing at 7.7% CAGR)

- Leverage Make in India branding for competitive advantage

10. Risk Assessment & Future Outlook

Market Opportunities

- Athleisure Boom: Growing demand for performance socks

- Sustainability Trend: Eco-friendly materials gaining traction

- E-commerce Growth: Online sales expanding rapidly

- Health Awareness: Compression and therapeutic socks market growing

Risk Mitigation

- Raw Material Volatility: Establish long-term supply contracts

- Competition: Focus on quality and unique designs

- Technology Obsolescence: Plan for machinery upgrades

- Market Fluctuations: Diversify product portfolio

Frequently Asked Questions (FAQs) About Starting a Profitable Socks Manufacturing Unit

1. What is the minimum investment required to start a socks manufacturing unit?

The minimum investment for a small-scale socks manufacturing unit is approximately ₹9.21 lakhs, including machinery, setup, and working capital.

2. What is the average profit margin for socks manufacturing?

Profit margins typically range from 15% to 25% for standard socks and can be higher for premium or designer products.

3. Which licenses are needed for a socks manufacturing business?

You will need GST registration, MSME/Udyog Aadhaar, Factory License, Pollution Control Board clearance, Fire NOC, and Trademark registration for your brand.

4. How many staff members are required for a small socks unit?

Generally, a small socks manufacturing unit requires 2–3 workers: 1 skilled machine operator and 1–2 helpers or packing staff.

5. What is the recommended plant size and location?

A facility of 1,200 sq ft in an industrial area, preferably in a textile hub like Uttarakhand, Haridwar, or Pantnagar, is recommended.socksManufacturingUnit.pdf

6. How do I source raw materials for socks manufacturing?

Raw materials such as polypropylene, blended yarn, and cotton can be sourced from established textile mills and fiber suppliers. Negotiate credit terms and maintain quality certifications.

7. What kind of machinery is required?

A standard setup includes a sock knitting machine, blender, finishing equipment, and packaging units. Investment is typically ₹6.5–7 lakhs plus GST.

8. How long does it take to break even in socks manufacturing?

Most units achieve break-even in 2–3 years, depending on capacity utilization and market demand.

9. Can socks manufacturing units avail government incentives?

Yes, states like Uttarakhand offer capital subsidies, interest rebates, power tariff discounts, and stamp duty exemptions for textile units.

10. How do I sell my products?

You can sell via wholesalers, local retailers, garment manufacturers, online marketplaces (Amazon, Flipkart), or export channels.

These answers should help entrepreneurs make informed decisions when planning or running a socks manufacturing unit.

- https://www.imarcgroup.com/socks-market

- https://www.drishtiias.com/daily-updates/daily-news-analysis/india-s-textile-industry

This comprehensive guide positions entrepreneurs to capitalize on India’s booming textile sector and the global socks market expansion, offering a clear roadmap from setup to profitability in the lucrative hosiery manufacturing industry.