Entrepreneurs can unlock significant growth by establishing a surgical 3-ply mask unit in Uttarakhand, with an estimated Indian market value of ₹438.7 million in 2025 and a 10.8% global CAGR through 2035. A modest ₹18.05 lakh investment, 1,200 sq ft plant, and 11-person team yield a break-even at 39% utilization and a 5-year payback with 2.36 DSCR.

1. Surgical 3-Ply Mask – Market Outlook & Growth Projection

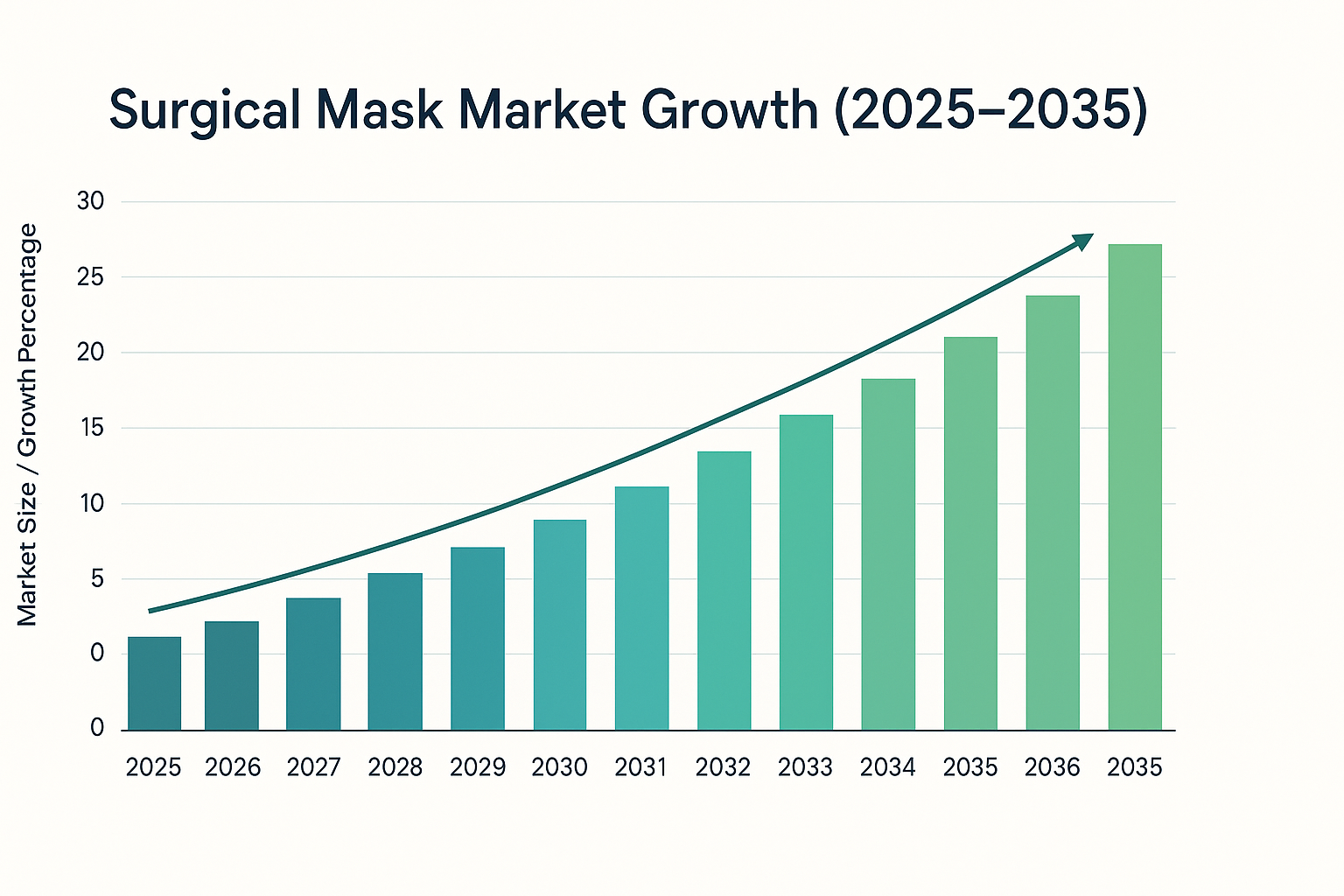

Global surgical mask demand reached USD 2,529 million in 2025, projected to soar to USD 7,052.5 million by 2035 at a 10.8% CAGR due to post-pandemic preparedness and stringent healthcare protocols. India’s face mask market will hit ₹438.74 million in 2025, growing at 1.08% CAGR through 2029.statista

| Region | 2025 Value | 2035 Projection | CAGR |

|---|---|---|---|

| Global | USD 2,529 M | USD 7,052.5 M | 10.8% |

| India | ₹438.74 M | – | 1.08% |

Chart of the global surgical mask market growth

2. Plant Location & Infrastructure

Example: Haridwar industrial estate, Uttarakhand

- Land & shed (1,200 sq ft) at ₹3,000/sq ft: ₹3.6 L

- Site development & utilities: ₹0.4 L

- Total infrastructure: ₹4.0 L

The layout includes raw material storage, production hall, quality lab, packaging area, and office.

3. Raw Materials: Sourcing & Costs

Annual requirements at full capacity (72 million masks):

| Material | Qty | Unit Cost | Annual Cost (₹) |

|---|---|---|---|

| Spun-bond PP (2×20 GSM + 15 GSM) | 13,250 kg | ₹130/kg | 1,722,500 |

| Elastic Ear Loop | 2,160,000 m | ₹0.50/m | 1,080,000 |

| Non-woven Nose Belt (20 mm) | 500 kg | ₹250/kg | 125,000 |

| Packaging (pouches, cartons) | – | – | – |

| Total | – | – | 2,927,500 |

Procurement Strategy

Source PP rolls and elastic from Panipat or Kollam at 3-month credit. Truckload (FTL) shipments to Dehradun/Haridwar minimize freight cost.

4. Machinery & Equipment

| Equipment | Qty | Cost (₹) | Function |

|---|---|---|---|

| Three-layer ultrasonic mask machine | 1 | 750,000 | Layer welding, pleating, cutting |

| Hot-press pleat setting unit | 1 | 150,000 | Stabilize pleats |

| Ultrasonic ear-loop welding module | 1 | 200,000 | Attach ear loops |

| Packaging machine (bagging & cartoning) | 1 | 350,000 | Automated packing |

| Conveyors, fixtures & misc. equipment | – | 50,000 | Material handling |

| Total Machinery Investment | – | ₹1,500,000 |

Financing mix: Term loan ₹11.25 L, equity ₹1.81 L, WC loan ₹5 L.3PlyMask.pdf

5. Manpower & Organization

| Role | Skilled/Unskilled | Headcount | Monthly Salary (₹) | Annual Cost (₹ lakh) |

|---|---|---|---|---|

| Machine Operators | Skilled | 2 | 12,000 | 2.88 |

| QC Inspector | Skilled | 1 | 15,000 | 1.80 |

| Maintenance Technician | Skilled | 1 | 14,000 | 1.68 |

| Unskilled Helpers | Unskilled | 4 | 8,000 | 4.32 |

| Packaging Staff | Unskilled | 2 | 8,000 | 2.16 |

| Admin & Sales Executive | Skilled | 1 | 20,000 | 2.40 |

| Total | – | 11 | – | 15.24 |

Add 10% fringe benefits on all wages.

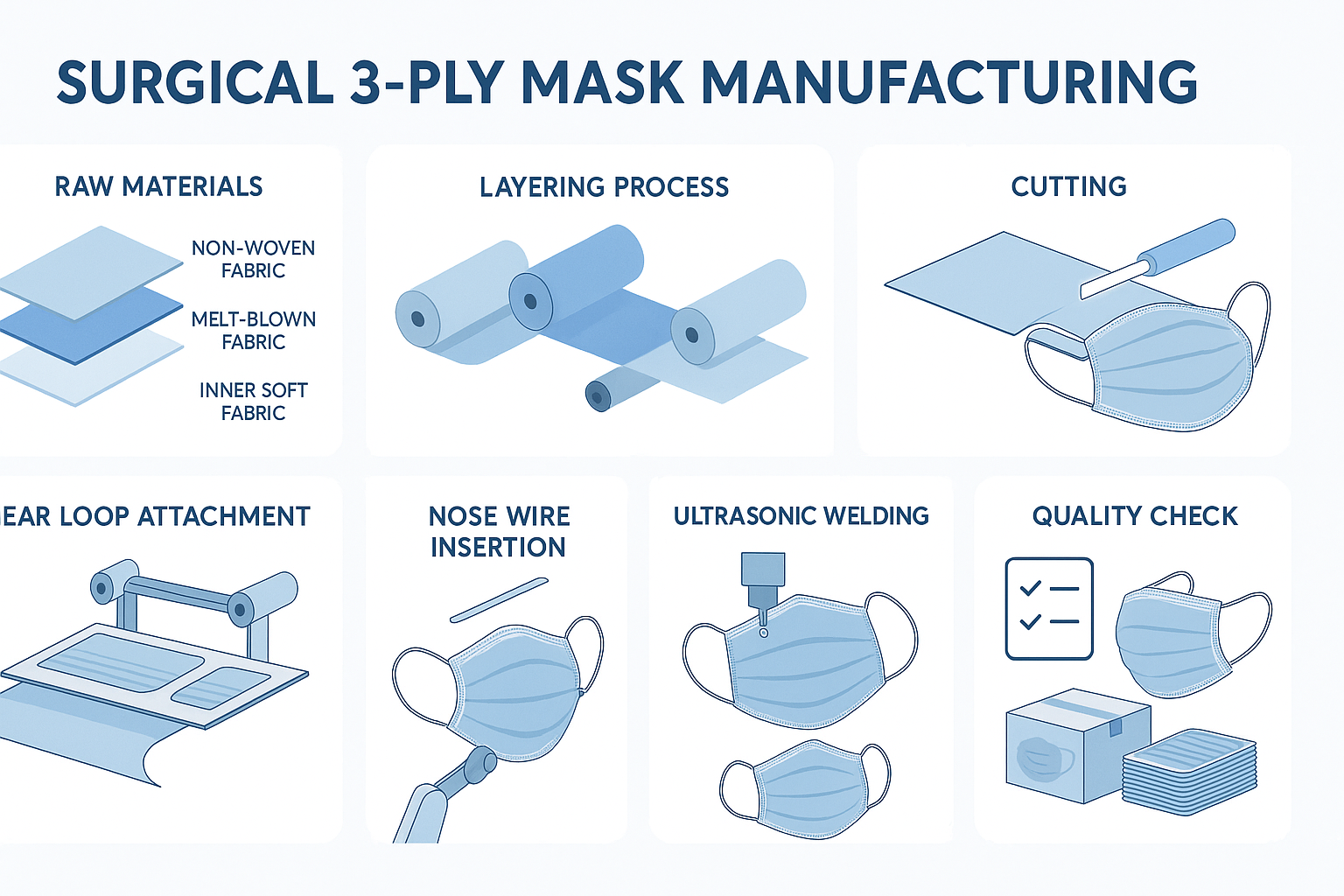

6. Production Workflow

- Raw Material Unwinding: Spun-bond and melt-blown PP rolls fed to ultrasonic welder.

- Three-Layer Welding: Edge-seam joins outer, filter, and inner layers.

- Pleat Formation: Hot-press sets a three-pleat design.

- Cutting & Ear-loop Welding: Masks cut, ear loops ultrasonically attached.

- Packaging: Automatic pouch filling and carton packing.

Infographic detailing Surgical 3-Ply Mask manufacturing steps

7. Operational Expenses

| Component | Annual Cost (₹ lakh) |

|---|---|

| Raw Materials | 29.28 |

| Utilities (Power & Diesel) | 1.98 |

| Salaries & Wages | 15.24 |

| Maintenance & Consumables | 0.60 |

| Interest (Term & WC) | 1.77 |

| Admin & Selling Expenses | 4.60 |

| Depreciation | 1.63 |

| Total Opex | 55.10 |

Electricity: 6 kW load, ₹7.50/unit, 8 hr/day, 300 days; DG set backup 0.5 hr/day.

8. Pricing, Profit & Break-Even

| Package | Selling Price | Cost/Box (₹) | Gross Margin | Net Margin (Year I–V) |

|---|---|---|---|---|

| 100-mask box | ₹100–₹122 | ₹40.66 | 59–67% | 4.5–15.2% |

| Single mask | ₹1.2–₹1.5 | ₹0.41 | 66–73% | 5–16% |

- Break-even: 39% utilization (~2.8 M masks/year)

- Payback: 5 years; DSCR 2.36

- ROI: 8.7% in Year I, rising to 50.3% by Year V

9. Logistics & Distribution

- Inbound: FTL shipments for raw materials to Uttarakhand, optimized routes to Dehradun.

- Outbound: 3PL distribution to hospitals, pharmacies, e-commerce; 20-day credit terms.

10. Regulatory, Incentives & Taxes

- Quality Standards: ISO 22609 splash resistance; ASTM F2100 BFE ≥ 95%; CDSCO/CE approvals.

- Uttarakhand Incentives: Capital & interest subsidies (25% capex), stamp duty exemptions, power tariff rebates.

- Central Schemes: Make in India benefits; MSME CGTMSE; GST @ 12% (input credit available).

11. Future Innovations – Surgical 3-Ply Mask

- Biodegradable melt-blown alternatives

- Smart masks with sensors

- Local sourcing to reduce import dependency

This comprehensive guide equips entrepreneurs with actionable insights, financial modeling, infrastructure planning, and policy frameworks to launch a profitable surgical 3-ply mask manufacturing unit in Uttarakhand.